The Ultimate Guide To Double Pane Glass Panels For Sale

Table of ContentsThe Ultimate Guide To Large Glazing PanelsSome Of Opaque Glazing PanelsOur Glazed Spandrel Panel PDFsIndicators on Double Pane Glass Panels You Need To Know8 Easy Facts About Double Pane Tempered Glass Panels ShownExcitement About Large Double Glazed Glass Panels

Sometimes, there are concerns associating with having way too much unrestrained daytime, in some cases described as glare. The difficulty is to pursue the highest visible light passage (VT) and also the lowest solar warm gain coefficient (SHGC) while not avoiding the glass from being too reflective when viewed from both the outside as well as the inside, while controlling glare.The systems should be entirely put together in a factory as well as delivered to the site for installation on the building. The systems are put on the floorings, bundled in cages, utilizing the tower crane and also lowered into area using a smaller crane or hoist had by the glazing contractor. The mullion dimensions have a tendency to be somewhat bigger than a stick system because of their open area as contrasted to television form of a standard stick drape wall section.

Rumored Buzz on Glazed Glass Panels

The interlocking vertical mullions will generally have two interlacing legs. One leg will certainly remain in the airplane just behind the glazing pocket and the various other at the indoor face of the mullions. The interlocking leg in the airplane of the glazing pocket will be secured by gaskets and also is the main line of defense against water and also air seepage - insulated glazing panels.

Equipments whose linking legs lock also endanger the capability of the system to accommodate activity. Some unitized designs are sensitive to tiny irregularities in the spacing of adjacent components; for instance, if the component joints are somewhat out of tolerance, gaskets may not be appropriately compressed and also moisture protection may suffer.

Top Guidelines Of Glazed Glass Panels

These upstanding legs have gaskets that seal versus the walls of the bottom straight. Some designs supply one upstanding leg that gives one line of defense against air and also water seepage. Much more durable systems will certainly give two upstanding legs with gaskets on both legs. A splice plate or silicone blinking that is mounted at the top of both surrounding units as they are set up on the building is usually called for.

The stack joint is the horizontal joint where systems from adjacent floors satisfy. Placing the stack joint at the sill of the vision glass (commonly 30" above the flooring) will certainly minimize the measurement of the vertical mullions. This positioning utilizes the back period of the mullion over the anchoring point at the piece to combat the deflection of the mullion listed below the slab.

The 5-Minute Rule for Double Pane Glass Panels

Area screening of drape wall surfaces: Call for the area testing of curtain wall surfaces for air seepage as well as water penetration resistance, for high quality assurance of curtain wall surface manufacture as well as installation. Call for numerous examinations with the very first test on initial installations and later examinations at about 35%, 70% and also at last completion to capture issues early as well as to confirm continued craftsmanship quality. double pane glass panels for sale.

The details linked with this section of the BEDG on the WBDG were developed by board as well as are intended exclusively as a way to illustrate general design as well as building and construction principles only. Proper use and also application of the concepts highlighted in these details will certainly vary based upon performance factors to consider and ecological conditions one-of-a-kind to every task and, consequently, do not represent the last point of view or recommendation of the author of each area or the committee participants in charge of the advancement of the WBDG.

Continuous metal sill flashing at the base of the curtain wall protects the wall surface framework listed below from leak with the drape wall surface. Sill more information blinking need to have upturned end dams as well as totally secured edges. Intermediate straight needs to be cried to the outside and prevent water from draining pipes onto the head of the glazing device below.

7 Easy Facts About Double Pane Glass Panels Described

Gasket height need to match to the curtain wall surface style stress. Pressure matched rainscreen gaskets form a key weather condition seal at the face of the unitized upright stack joint in line with the horizontal rainscreen gasket at the device sill listed below.

Spandrel glass adapters are utilized to minimize the deepness of the glazing pocket to accommodate reduced account of spandrel glass. Spandrel glass adapters must be fully bedded in sealant as well as incorporated with polishing pocket edge seals to avoid water leak from polishing pocket to structure interior. right here Device dimension of breeding head and sill squeezed out accounts enables for defined flooring to flooring deflection at the pile joint.

Intermediate horizontals stop at the face of the upright device jamb members at each end. Systems are hung from the leading or face of the nearby find here flooring or building framework utilizing mated braces as well as field applied bolts with a minimum of clearance for accessibility and also setting up. All connections and brackets located within the units shielded or key climate seal zones are sealed with suitable sealant products throughout field setup.

Glazed Wall Panels Fundamentals Explained

non-heat-treated) or totally toughened up glass to continue to be in location till it can be changed. glazed glass panels. Whether heat-strengthened or completely tempered, heat-treated glass items are produced in a comparable fashion and also utilizing the exact same processing tools. The glass is heated to approximately 650 C (1200 F), after that force-cooled to produce surface area and also edge compression.

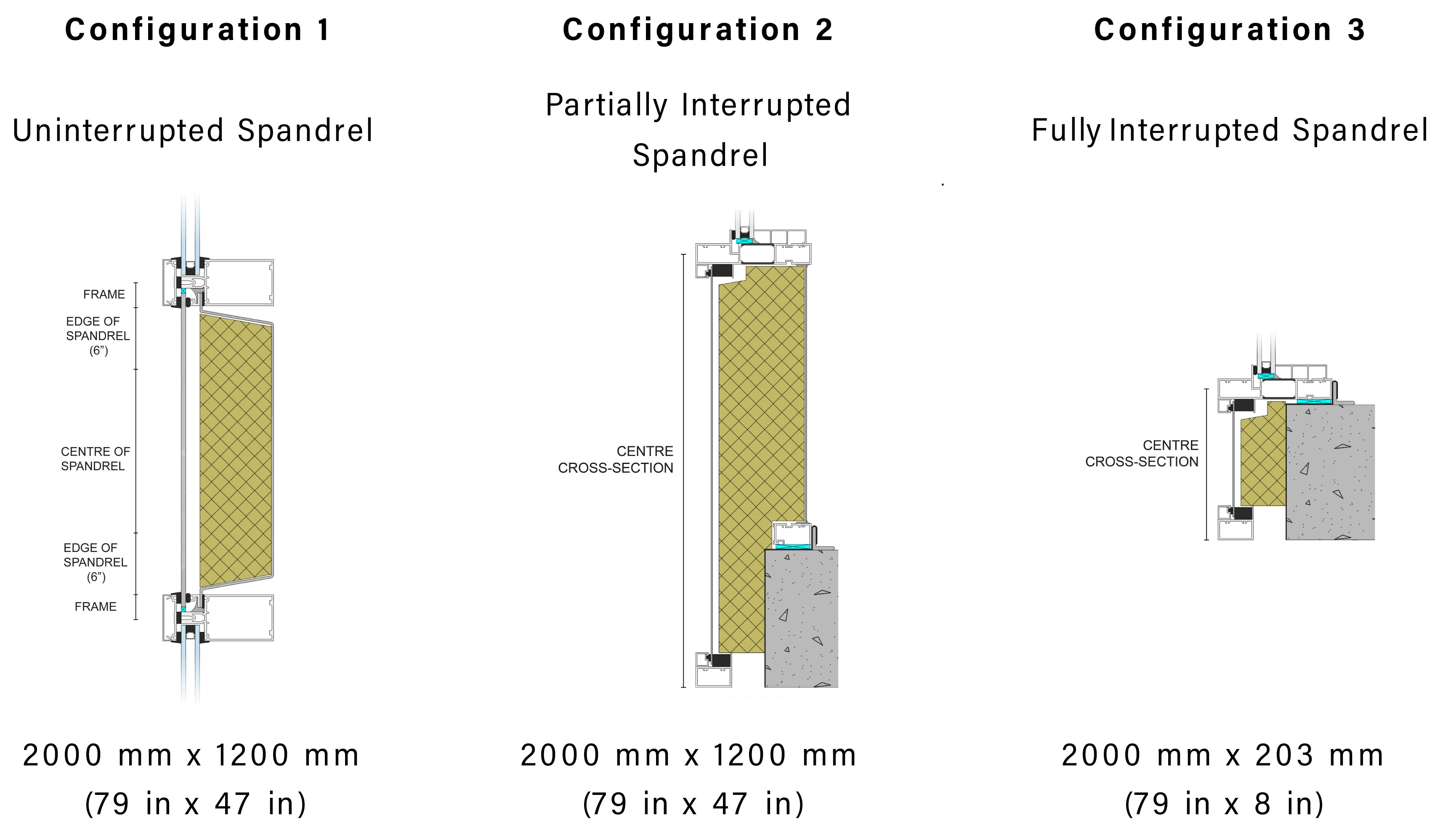

As shown in Figure 1, insulation is frequently used in combination with spandrel glass. When the insulation is to be applied straight to the opacified surface area of the spandrel glass, it is necessary to deal with a glass spandrel fabricator, along with the glue and also insulation providers, to make certain these items work with the opacifying material.